Deluge Alarm Valve for Fire Fighting

Basic Info

| Model NO. | ZSFM80 |

| Type | Outdoor Fire Hydrant |

| Decompression | Normal Fire Hydrant |

| Rotation | Ordinary Bolt |

| Outdoor Fire Hydrant Type | High-Pressure Fire Hydrant |

| Fire Hydrant Type | Ordinary |

| Rate Working Pressure | 12bar |

| Seal Test | 24bar |

| Strength Test | 48bar |

| Transport Package | Packing by Wood Box |

| Specification | ZSFM80 |

| Trademark | sanxing |

| Origin | Quanzhou, Fujian, China |

| HS Code | 8481804090 |

Product Description

product description

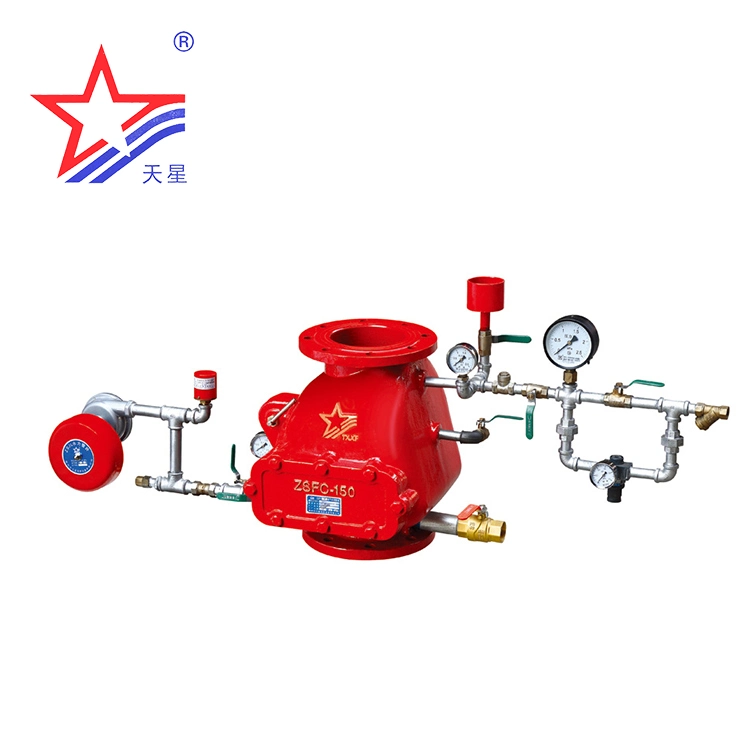

the shower valve is a direct-sealed diaphragm valve.the valve body is made of high-quality cast iron.the diaphragm is made of cloth-butyl rubber material.

it has the characteristics of durability,reliable performance,flexible installation and convenient maintenance.

there are no components such as shafts and metak discs in the valve,so there is no problem of corrosion.

it is widely used in variousopen systems (open sprinklers on the system side pipes)such as rain shower systems,water curtain systems,and water mist systems.

this valve is manufactured according to GB5135.5-2003 standard.the rain sprinkler valve and various open sprinklers form a rain sprinkler system,also an open fire suppression system.

once the rain sprinkler valve is opened,all open sprinklers connected behind the valve spray water at the same time,so the rain sprinkler system is suitable for high-speed fire spreading ,and the closed sprinklercan not effectively cover the fire area when the sprinkler is opened,due to the high space,the closed sprinkler cannot move in time.such as stage,pyrotechnic factory and other places with serious danger level ll(solvent,paint,asphalt,etc.).

because the rain shower system is a facility with a single active area,it must be designed accoring to specifictions.the protection range of a rain shower valve must not exceed 260m2.

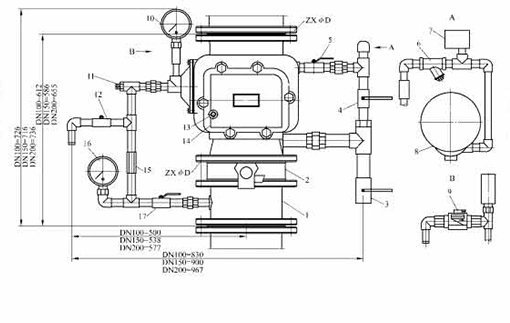

technical parameters

| specification | ZSFM65 | ZSFM80 | ZSFM100 | ZSFM125 | ZSFM150 | ZSFM200 | ZSFM250 |

| rate working pressure(Mpa) | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| seal test(Mpa) | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 |

| strength test(Mpa) | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 | 4.8 |

| nominal diameter(mm) | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 | DN250 |

| flange diameter(Mpa) | 185 | 200 | 220 | 220 | 285 | 340 | 405 |

| sysmmetric hole diameter(mm) | 145 | 160 | 180 | 180 | 240 | 295 | 355 |

| screw hole number and diameter(mm) | 4*18 | 8*18 | 8*18 | 8*18 | 8*22 | 12*22 | 12*26 |

working principle