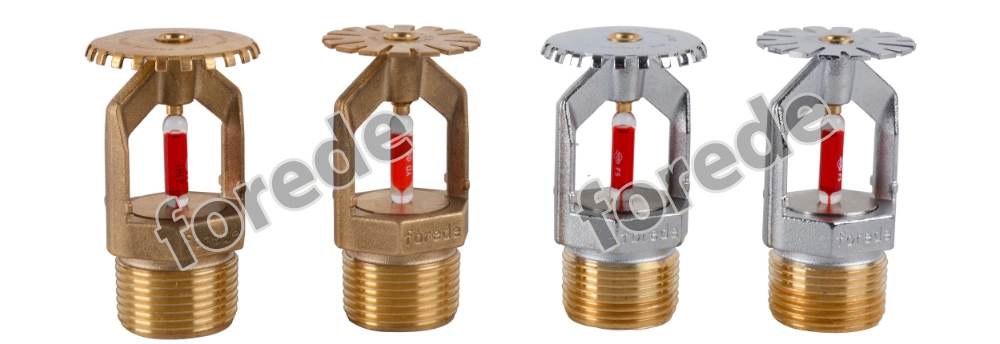

Frd-004 K11.2 Brass Pendent Upright Fire Sprinkler for Fire Sprinkler System

Overview Product Description K=11.2 FIRE SPRINKLER FOREDE Series FRD004/FRD005 11.2K Standard Response, Standard Coverag;

Basic Info

| Model NO. | FRD-004 |

| Sprinkler Installation | Pendent;Upright |

| Sprinkler Head Type | Closed |

| Alarm Valve Type | Wet Alarm Valve |

| Automatically Opened and Closed Repeatedly | Can Automatically Opened and Closed |

| Open Fire Sprinkler System Type | Deluge System |

| Closed Fire Sprinkler System | Wet Fire Sprinkler System |

| Dry Alarm Valve Type | Differential Type |

| Wet Alarm Valve Structure | Seat Type |

| Alarm Valve Diameter | 100mm |

| Nozzle Flow Coefficient | K11.2(161) |

| Deluge Valve Type | Diaphragm Type |

| Product Name | K11.2 Brass Pendent Upright Fire Sprinkler |

| Finish | Chrome; Original |

| Connection | Bsp |

| Material | Brass |

| Temperature | 68 Degree |

| OEM | Workable, MOQ=5000PCS |

| Listings and Approvals | Cccf,ISO9001, ISO14001 |

| Transport Package | Carton |

| Specification | 65*50*50 |

| Trademark | FOREDE |

| Origin | Fujian, China |

| HS Code | 8424901000 |

| Production Capacity | 200000sets/Month |

Product Description

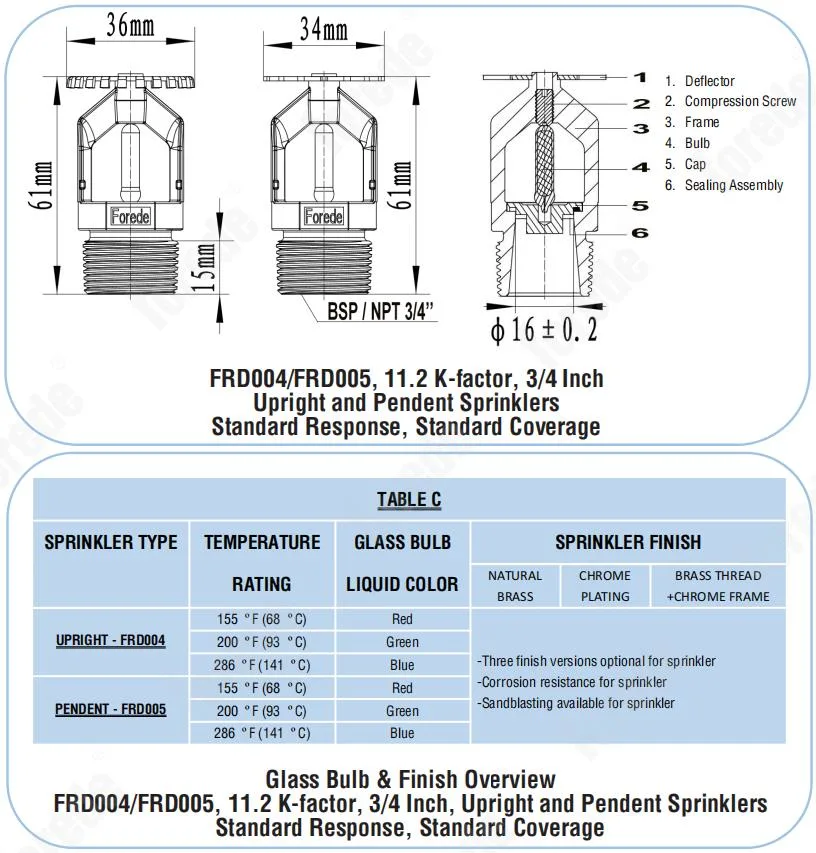

K=11.2 FIRE SPRINKLERFOREDE Series FRD004/FRD005 11.2K Standard Response, Standard Coverage Upright and Pendent Sprinklers are automatic sprinklers of the frangible bulb type. They are standard response, spray sprinklers that produce a hemi-

spherical water distribution pattern below the deflector.

The 11.2 K-factor, FRD004/FRD005 Sprinklers were subjected to full-scale, high-piled storage fire tests to qualify their use in lieu of 5.6 or 8.0 K-factor standard spray sprinklers for the protection of high-piled storage.

Higher flow rates can be achieved at much lower pressures with the 11.2 K-factor, FRD004/FRD005 Sprinklers, making their use highly advantageous in high density applications, such as the protection of high-piled storage.

Chrome coatings can be used to extend the life of the brass components used in Series FRD004/FRD005 Sprinklers beyond that which would otherwise be obtained when exposed to corrosive atmospheres. Although coated sprinklers have passed the standard corrosion tests of the applicable approval agencies, the testing is not representative of all possible corrosive atmospheres. Consequently, it is recommended that the end-user be consulted with respect to the suitability of these corrosion resistant coatings for any given corrosive environment. The effects of ambient temperature, concentration of chemicals, and gas/chemical velocity, should be considered, as a minimum, along with the corrosive nature of the chemical to which the sprinklers will be exposed.Specification

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Sealing Assembly Glass bulb 5mm. . . . . .Glass Compression Screw . . . . . . . . . . . . . . . . .Brass Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .BrassRefer to TABLE A & TABLE B for additional technical data.

| TABLE A | |

| MODEL | FRD004 |

| WORKING PRESSURE | 175 psi (12,1 bar) |

| CONNECTION | 3/4'' BSP (NPT OPTIONAL) |

| K-FACTOR | 11.2 GPM/psi½ (161,4 LPM/bar½) |

| TEMPERATURE RATING | 155 ºF (68 ºC) 200 ºF (93 ºC) 286 ºF (141 ºC) |

| INSTALLATION | Upright |

| TABLE B | |

| MODEL | FRD005 |

| WORKING PRESSURE | 175 psi (12,1 bar) |

| CONNECTION | 3/4'' BSP (NPT OPTIONAL) |

| K-FACTOR | 11.2 GPM/psi½ (161,4 LPM/bar½) |

| TEMPERATURE RATING | 155 ºF (68 ºC) 200 ºF (93 ºC) 286 ºF (141 ºC) |

| INSTALLATION | Pendent |

Before ordering, please contact with our sales team to discuss order information.

If you have any other requirements or wanna know more info about our products, welcome to contact as well. Our Sales team and Technical Department are willing to support you.

You may also like

Send inquiry

Send now